The ecommerce landscape is rapidly evolving, driven by changing consumer demands and market dynamics. Within this fast-paced environment, the efficiency of supply chains becomes a critical factor for success. An often overlooked yet vital component of these supply chains is reverse logistics. This aspect significantly affects a business’s operational flexibility, cost-effectiveness, environmental sustainability, and customer satisfaction.

What is Reverse Logistics?

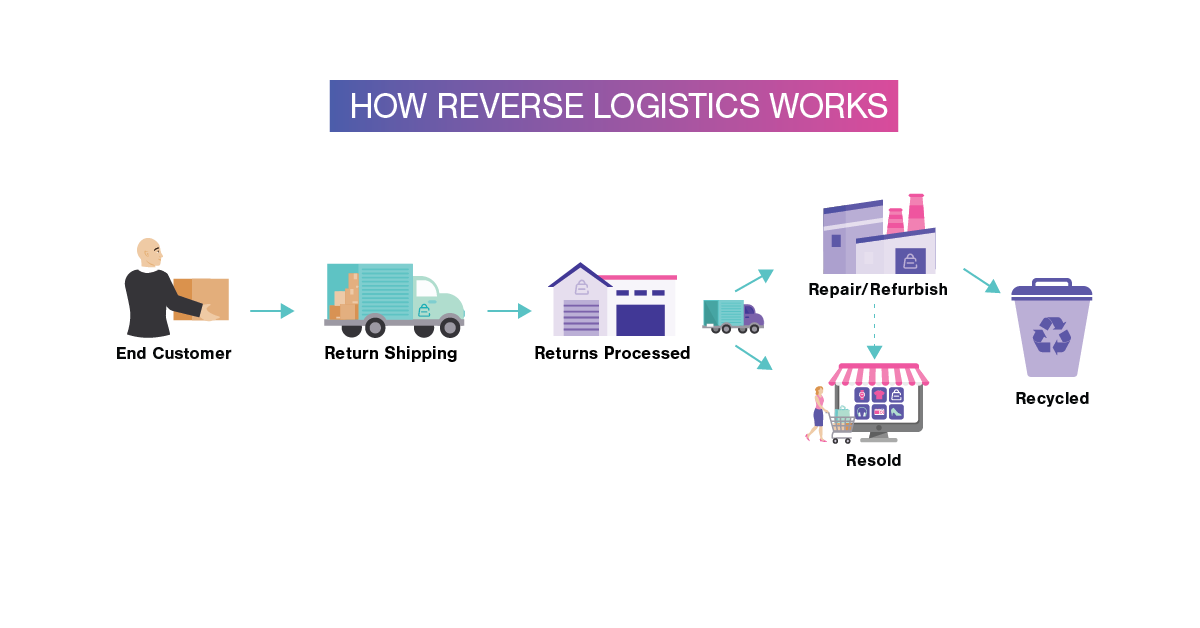

Reverse logistics is a critical yet often understated aspect of supply chain management, dealing with the return journey of products from the customer to the seller or manufacturer. This process involves reversing the traditional supply chain flow, where goods move from their final destination back to their point of origin for various reasons such as return, repair, recycling, or disposal.

The complexity of reverse logistics arises from its multifaceted nature. It’s not merely about ferrying returned goods from point A to B. Encompassing a wide array of activities, it’s a spectrum that extends to inspecting the items, restocking them, processing refunds, dealing with waste management, and much more. This rich tapestry of operations forms the backbone of what we call the reverse supply chain.

From the moment a customer decides to return a product, the reverse supply chain kicks into action. Rather than a linear path, it’s a web of interconnected processes designed to handle returns efficiently. The goal is to optimize recovery value or ensure proper disposal. Reverse logistics encompasses a wide range of activities:

Return Management:

This includes handling customer returns due to dissatisfaction, defects, or delivery errors. Effective return management requires a seamless process that ensures customer convenience while maintaining cost efficiency for the company. In order to optimize reverse logistics, companies must prioritize efficient repackaging strategies that allow for the swift handling, sorting, sorting, and refurbishment of returned products.

As part of reverse logistics, the returns management process is essential for retailers and manufacturers. It is centered around the concept of asset recovery, seeking to regain the maximum value from returned, overstocked, or unused products to increase revenue. Precise execution of this process can significantly improve your bottom line, turning potential losses into profits.

As a retailer, you may need to send products back to different manufacturers for repair or even get your money back.

Repair and Refurbishment:

Products that are returned due to defects or damage often undergo repair or refurbishment. This process involves assessing the item’s condition, performing necessary repairs, and restoring it to a sellable state, if possible.

Reverse logistics looks to reintroduce these revamped products back into the market through redistribution. After repairing, refurbishing, remanufacturing, or reconditioning, your products are ready for a market comeback. It’s now up to you to reappraise their value, propose a competitive price, and navigate them back to the sales window quickly and efficiently. This process of distributing products back into the marketplace is crucial in making the most out of your returned goods.

Recycling and Waste Management:

A significant aspect of reverse logistics is addressing products that are unsellable. Here, the principle of reusing comes into play, where recyclable materials are optimally harvested and subsequently reused, contributing to the economy. This process leverages trucks for transportation across cities and ensures that landfills are responsibly managed by minimizing waste disposal, thereby promoting environmental sustainability.

Inventory Management:

Managing the returned products as inventory is another crucial aspect. This involves tracking items, assessing their condition, and determining the most appropriate subsequent action, whether it’s resale, recycling, or disposal.

In the realm of ecommerce, the role and importance of reverse logistics in the supply chain are magnified. The online shopping model inherently leads to a higher volume of returns compared to traditional retail. Reasons include customers’ inability to physically inspect products before purchase, product appearance or function variations from online descriptions, and the ease of return policies offered by ecommerce platforms.

The Importance of Focusing on Reverse Logistics

Emphasizing reverse logistics is crucial for businesses in the digital marketplace, as it impacts several key areas of operations, each contributing significantly to overall success.

Whether a retailer or manufacturer navigating customer returns or a company managing end-of-life products, understanding and strategically implementing reverse logistics can unlock many benefits.

Enhancing Operational Efficiency

Effective reverse logistics goes beyond mere cost savings; it’s about enhancing overall operational efficiency. By refining the process of handling returns, businesses can streamline workflows, reduce bottlenecks, and optimize resource allocation. This efficiency not only cuts down on unnecessary expenditures but also speeds up the return-to-market of refurbished goods, maximizing asset utilization.

Driving Sustainable Practices

The focus on reverse logistics is increasingly intertwined with sustainability goals. Effective management of this aspect ensures the responsible handling of product lifecycles, from returns to final disposal. By implementing sustainable practices in reverse logistics, companies not only contribute to environmental conservation but also align with the growing consumer preference for eco-friendly businesses. This approach includes minimizing waste through innovative recycling programs and finding new ways to repurpose returned goods.

Bolstering Customer Relations

In the realm of ecommerce, the ease and flexibility of the return process are often as important as the initial purchase experience. A customer-centric approach in reverse logistics—characterized by clear communication, convenient return policies, and responsive service—can significantly enhance customer satisfaction. This focus helps in building a positive reputation, long-term relationships with customers, encouraging repeat business, and positive word-of-mouth.

Providing Strategic Business Insights

Reverse logistics is a rich source of data that can offer valuable business insights. Analyzing trends in returns and customer feedback can highlight areas for product improvement, reveal insights about customer preferences, and inform strategic decisions. This information is vital for adapting product offerings, refining marketing strategies, and enhancing overall business operations.

Readiness for Market Shifts and Regulatory Compliance

A robust reverse logistics strategy positions businesses to better adapt to market shifts and regulatory changes. As consumer habits evolve and regulations around sustainability and waste management become more stringent, a well-structured reverse logistics process ensures businesses remain agile and compliant.

Long-term Financial Health

While initially focused on immediate cost reductions, the long-term financial health of a business greatly benefits from an effective reverse logistics strategy. Companies can improve their financial resilience and profitability by reducing losses associated with returns, extending the life of products through refurbishment, and capitalizing on recycling opportunities.

Prioritizing reverse logistics is not just about managing returns but encompasses a broader strategy that touches upon operational efficiency, environmental responsibility, customer satisfaction, business intelligence, regulatory readiness, and financial stability. It’s an integral part of modern business practices, especially in the ecommerce sector, where its impact is even more pronounced.

The Impact of Ecommerce on Reverse Logistics

The growth of ecommerce has substantially altered consumer purchasing behaviors, leading to an increase in product returns. This shift has necessitated a reevaluation of reverse logistics strategies, elevating this function from a logistical afterthought to a key element of customer service. Today, businesses face the challenge of efficiently managing high volumes of returns while controlling logistics costs and maintaining positive customer experiences. In response, many ecommerce companies have adopted more flexible return policies and invested in advanced technologies to automate and streamline return processes.

Examples of Reverse Logistics

The classic example of reverse logistics is when a car manufacturer recalls a line of cars due to safety concerns. The process of retrieving these vehicles and returning them to the manufacturer is an excellent example of reverse logistics at work in the industry. Your business must be equipped to handle a product recall.

Imagine you’re the owner of a clothing company. A customer wants to return a dress that didn’t fit. This is a typical example of reverse logistics – your company needs to arrange the transportation of the dress back from the customer, inspect and restock the item, or discard it accordingly. This process not only involves logistics but also customer services and quality control.

Another representative example is seen in the electronics industry. Consider you’ve purchased a new smartphone, and after a few weeks, it starts malfunctioning. Under the warranty’s terms, you return the device to the manufacturer. Here, reverse logistics come into play – this involves handling the return shipment, tracking the returned product, evaluating its condition, providing a replacement or refund to the customer, and possibly refurbishing or recycling the defective device.

A less well-known but equally valuable example involves recycling initiatives. Suppose you are part of a city council that sets up a recycling program where the residents can return used batteries for safe disposal. These batteries’ collection, transportation, and disposal represent an instance of reverse logistics. Such initiatives help promote environmental sustainability while addressing hazardous materials appropriately.

Technology’s Crucial Role in Enhancing Reverse Logistics

Let’s dive right into how technology plays a pivotal role in enhancing reverse logistics. As you may know, reverse logistics can be a complex and challenging process. It involves handling returned products, processing refunds, dealing with customer complaints, and reallocating resources. But here’s the good news. Thanks to technology, companies can now streamline these procedures and pave the way for efficiency and customer satisfaction.

Technology now takes center stage in managing reverse logistics, from shipping software to automated return systems. Let’s take a closer look at these pivotal technological advancements.

Return Management Systems

Return management systems, often called RMA (Return Merchandise Authorization) systems, play a key role in systematically processing returns. Tracking, handling, and analyzing returns has never been easier with this technology. More importantly, RMA systems can give emotionally charged situations – like returns – a sorted, hassle-free approach, thereby enhancing customer satisfaction.

Warehouse Management Systems (WMS)

Remember the times when returns would come in, creating chaos in warehouses? Well, those days are long gone. Using Warehouse Management Systems (WMS), companies can now handle returns with ease, allocating resources, managing stocks, and processing returns efficiently.

Real-time Tracking

Real-time tracking empowers not just the sellers but the customers as well. Customers can have full visibility of their returns process right from filing a return to processing a refund, adding an extra layer of transparency to the whole process. On the business front, this enables businesses to make well-informed, strategic decisions based on real-time data.

To sum it up, technology has indeed revolutionized reverse logistics. It’s all about efficiency and effectiveness, ensuring a smooth, hassle-free return process for both the customer and the company to maximize revenue. Navigating the complex maze of return logistics just got a lot easier, thanks to the wonders of technology.

AI and Automation

As you delve deeper into the technological aspects of reverse logistics, you can’t overlook the revolutionary roles of Artificial Intelligence (AI) and automation. These are not just buzzwords but key driving forces in the effective operation of reverse logistics. AI and automation help businesses streamline their returns process, maximize efficiency, and minimize human error.

This is achievable by automating return authorization and processing, improving warehouse management and transportation, and reducing unnecessary costs. Conversely, AI uses machine learning techniques to effectively analyze return patterns, customer behaviors, and product life cycles, helping companies make informed decisions on reselling, refurbishing, recycling, or discarding returned products. Moreover, predictive analytics enabled by AI can provide valuable insight suggesting specific actions to prevent potential product returns and improve customer satisfaction.

With clear advantages of incorporating AI and automation into reverse logistics, businesses are equipped with robust tools making them more responsive and agile in the complex and competitive marketplace. So remember, embracing AI and automation is not just an option, it’s a strategic move to stay ahead in the game. For more in-depth insights into AI and automation in reverse logistics, you can refer to this research article, “AI and Automation in Reverse Logistics”.

Strategies for Reverse Logistics Optimization

Optimizing your reverse logistics can make a monumental difference in your business operations, improving customer service, reducing costs, and increasing overall efficiency. But to unlock these benefits, you’ll need to implement some strategic steps. Here are some best practices you could consider:

- Clear return policy: Good communication is the essence of smooth reverse logistics. Make your return policies as clear and straightforward as possible. Provide detailed procedures on how customers can return their purchases to minimize confusion and improve the return process.

- Efficient return process: Time is of the essence in reverse logistics. The more efficient your return processes are, the quicker items can be restocked or disposed of, reducing inventory costs. Consider using technology like automation and real-time tracking to increase efficiency.

- Product Life-cycle Management: Understanding the lifecycle of your products can significantly impact your reverse logistics. By being aware of each product’s lifecycle, you can anticipate returns and prepare appropriately to manage the returned inventory.

- Examine and act on customer behavior: Use data analytics to understand why customers are returning items. This information can help reduce return rates in the future by addressing common issues, such as product quality or misleading product descriptions. This can have a huge impact on long-term customer retention.

- Partner with expert third-party logistics (3PL) providers: Collaborating with experienced 3PL providers can help optimize your reverse logistics. These companies have the expertise and resources to handle large-scale and complex reverse logistics operations.

Beyond these strategies, it’s critical always to improve, test, and iterate your reverse logistics over time. Remember, a successful reverse logistics strategy isn’t a set-it-and-forget-it process; it’s a continually evolving system that should adapt based on ongoing developments and the changing needs of your business and customers.

Choosing a Reverse Logistics Partner: Key Considerations

When navigating the complexities of reverse logistics, choosing the right partner is a crucial decision. Several key factors must be considered:

Technology and Innovation

A competent reverse logistics partner should utilize cutting-edge technology to enhance the return process. This includes the adoption of real-time tracking systems, the use of AI for predictive analytics, and the integration of automation technologies to improve efficiency. This tech-driven approach reduces errors and provides actionable insights through data analysis, which is essential for informed decision-making and strategic planning.

Sustainability Practices

The environmental impact of reverse logistics is increasingly a concern for businesses and consumers alike. It’s vital to partner with organizations that are committed to environmental sustainability. This includes employing sustainable packaging solutions, optimizing logistics routes to reduce carbon emissions, and engaging in product recycling and reuse initiatives.

Customer Experience Focus

The way a partner handles customer experience is another crucial factor. This includes having clear and straightforward return policies, a user-friendly return process, and a responsive customer support system. Providing an effortless and transparent return experience can significantly boost customer satisfaction and loyalty, reinforcing a positive brand image.

Reinventing Your Supply Chain with Reverse Logistics

In the dynamic world of eCommerce, the efficiency of reverse logistics is just as crucial as the direct shipping process. Understanding this, ShipNetwork includes reverse logistics in its array of logistics solutions, aiming to streamline the return process for eCommerce businesses.

This holistic approach plays a pivotal role in enhancing customer satisfaction and optimizing operational efficiency. Effectively managing returns is key to fostering customer loyalty and growth, and ShipNetwork’s inclusion of reverse logistics in its services underlines its commitment to offering comprehensive support for eCommerce businesses.

Reverse logistics is an indispensable component of the ecommerce ecosystem, playing a crucial role in maintaining operational efficiency, reducing costs, and enhancing customer satisfaction. In an era marked by rapidly changing consumer expectations and intense market competition, the effective management of reverse logistics is not just an operational need but a strategic imperative.

By focusing on this critical aspect and partnering with the right logistics providers, companies can ensure enhanced efficiency, sustainability, and customer loyalty, solidifying their position in the dynamic world of ecommerce.